Simulation of Advanced Manufacturing Technologies

LTSM is activated in the simulation of forming and joining of metallic and composite structural parts using numerical methods. Some of the LTSM''s activities in this area are:

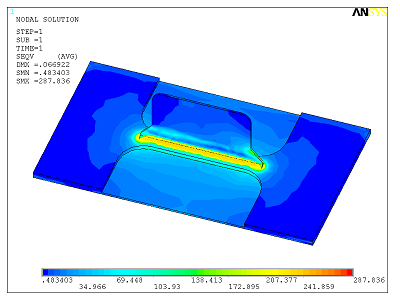

- Simulation of laser welding of metals and polymers,

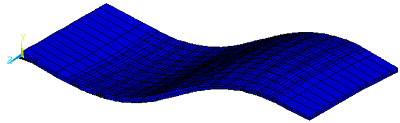

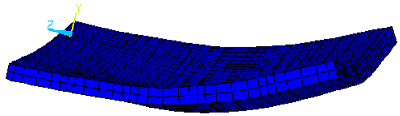

- Simulation of laser forming of metallic sheets, and

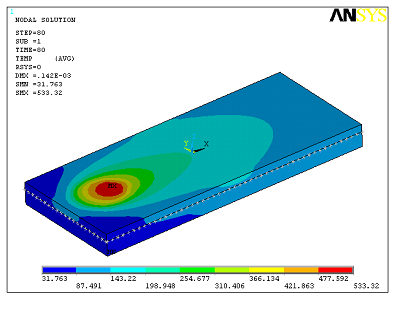

- Simulation of friction stir welding in metallic sheets.

Prediction of residual stress distribution due to laser welding.

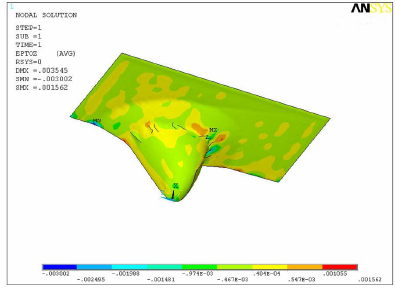

Prediction of deformation and buckling angle in metallic sheets due to laser forming.