Mechanical Behavior of Materials

Experimental characterization of the mechanical behavior of metallic and composite materials under static, quasi-static and dynamic loads is one of the most important research sectors of LTSM. The specific activities of LTSM in this area are the following:

Mechanical behavior under quasi-static loads (tension, compression, bending, torsion, buckling, fracture toughness, etc)

Fatigue

-

Derivation of S-N curves and fatigue crack-growth curves,

-

Effect of overloads and load interaction on the fatigue crack growth,

-

Effect of alloy ingredients on fatigue crack growth, and

-

Effect of microstructure on fracture behavior.

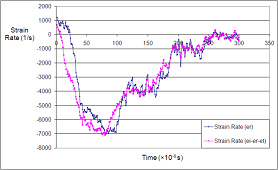

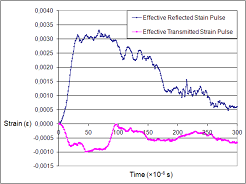

High-strain rate mechanical tests (split Hopkinson bars)

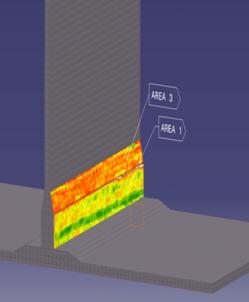

Non-destructive testing and metallographic characterization

- Hardness test,

- Ultrasound inspection,

- Metallographic characterization,

- Fractographic analysis, and

- Corrosion characterization.

High temperature testing

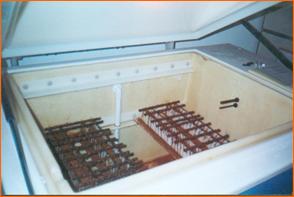

- Creep tests, and

- Testing in environmental chamber.

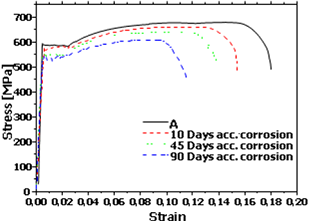

Corrosion tests

- Exposure to atmospheric corrosion,

- Tests with caustic spray,

- Split-up under tension and corrosion.

3-point bending test in a composite bonded joint

Split Hopkinson tests

| Effect of corrosion on the mechanical properties of metallic bars used as concrete reinforcements | C-scan image of an adhesively bonded joint between composite plates |