Optimization of Composite Aerostructures

Analysis and optimization of small- and large-scale composite aerostructrures is an important research area of LTSM. The basic tool in this process is the FE method. Moreover, in LTSM, a progressive damage modeling technique has been developed for predicting the mechanical performance and strength of composite parts by simulating progression of all damage types in composite materials. The method has been applied to unidirectional composite laminates and textile composites. Some of the applications that have been made in this area are:

- Strength prediction of composite bolted joints,

- Optimization of composite bonded joints,

- Analysis of the composite adhesively bonded flap-track beam of Airbus A400M, and

- Analysis and optimization of a composite multi-spar wing.

Flowchart of the progressive damage model.

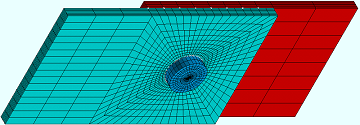

| FE model of a composite bolted joint. | FE mesh (front-view) of the Pi-shaped bonded joint with an indication of the assembled parts. |

|

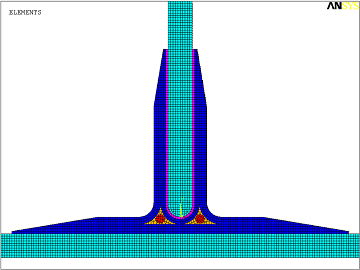

Prediction of damage progression in the composite laminate of the bolted joint. |

Prediction of debonding progression due to adhesive shearing. |

| The composite adhesively bonded flap-track beam of A400M. |

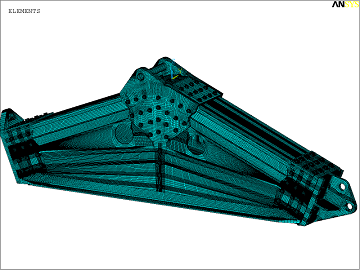

FE model of the Airbus A400M flap-track beam.

|

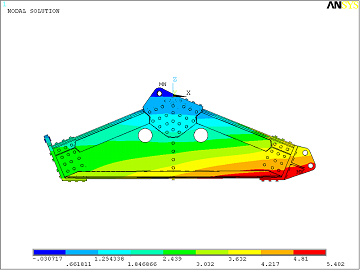

Prediction of the longitudinal stress distribution in the flap-track beam.

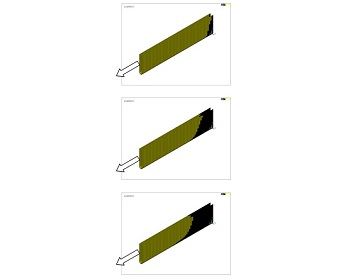

FE models of multi-spar wings with different reinforcing beams.